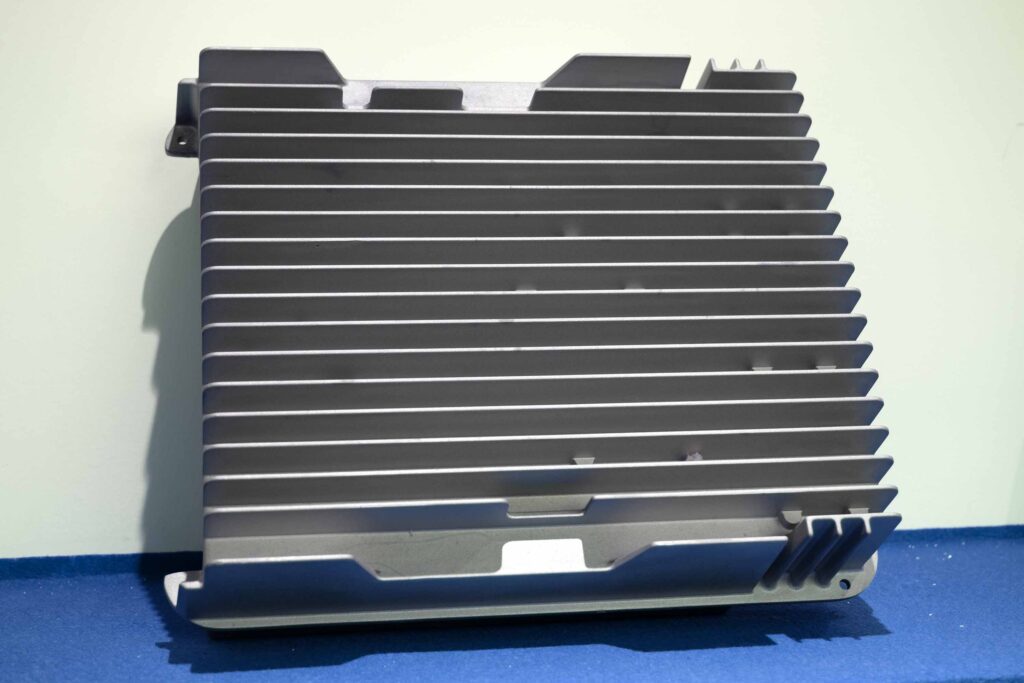

This product is an environmentally friendly, high-grade baking tray. It is manufactured using high-precision aluminum die casting, achieving lightweight design and high-strength structure. After initial polishing, precision machining of the back positioning holes is performed.

The surface is first sandblasted to enhance adhesion, followed by ceramic coating. The challenge lies in the poor adhesion of ceramic powder and the strict thickness control of 20–45 μm; excessive thickness may cause chipping, while insufficient thickness can lead to peeling. During heating, care must be taken to prevent the ceramic from sliding under gravity.

To address these challenges, we use high-quality raw materials to ensure purity and stability of the ceramic powder. A customized production line with uniform spray gun systems is employed to achieve consistent powder deposition and precise process control. Finally, natural gas heating with temperature control ensures uniform curing of the coating.