Equipment and working environment

Empowering Excellence Through Precision and Advanced Equipment.

Equipment and working environment

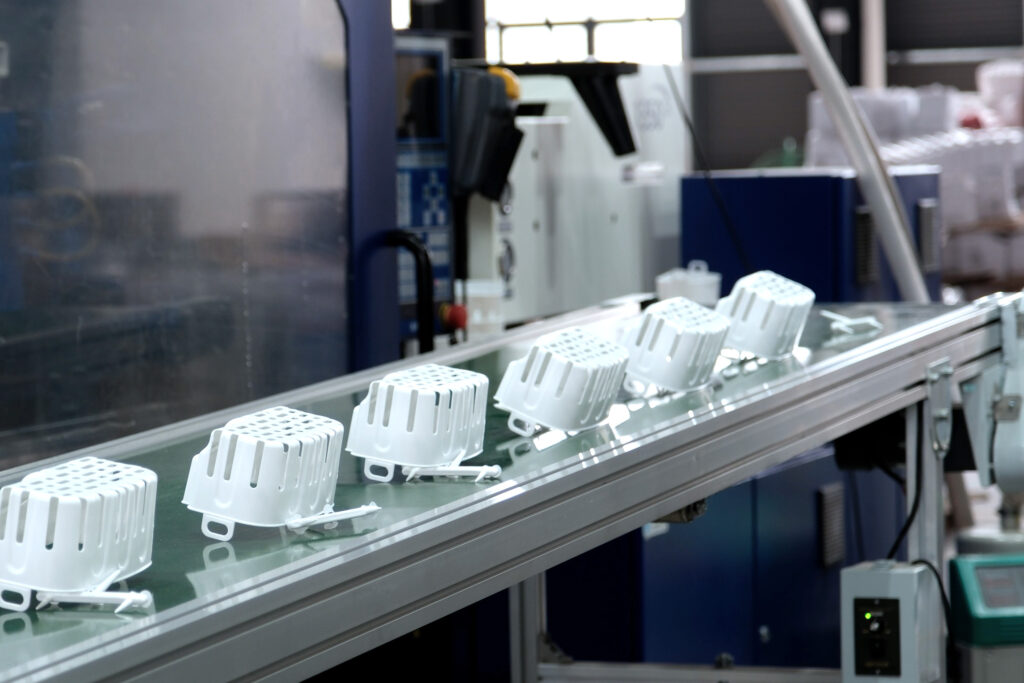

At TIANTEC, all our equipment and working environments are designed around quality, efficiency, and scientifically planned layouts. Professional mold manufacturing and extensive injection molding experience form the cornerstone of our capabilities. Building on our strong foundation in precision machining, TIANTEC now provides clients with the most comprehensive and cost-effective one-stop solutions in the field of metal processing and surface treatment. None of this would be possible without the support of our advanced equipment.

mold development Workshops

Injection Molding Workshops

Machining Workshops

Forming and Processing Workshops

Surface treatment Workshops