Hardware Project Cases

A closer look at how we create tailored solutions and continuously deliver exceptional value to our clients.

Hardware product Cases

PVD Titanium-Coated Stainless Steel Sanitary Component

This component is used in the high-end sanitary sector. It is made from high-strength stainless steel and formed through hot forging, ensuring high density and excellent impact resistance. CNC precision machining is then applied to achieve tight dimensional tolerances and complex structures, meeting customer requirements for accuracy and assembly. The surface is polished and electroplated, followed by PVD titanium coating, providing excellent corrosion resistance, wear resistance, and premium decorative appeal.

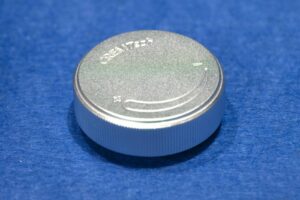

Metal Control Knob

This component is used in high-end home appliances as a functional and aesthetic control knob, enhancing the overall product quality and user experience. It is manufactured by aluminum die casting, with CNC chamfering applied to the edges to ensure a comfortable feel and smooth assembly. The surface undergoes polishing and anodizing, achieving a matte finish while providing wear resistance, fingerprint resistance, and aesthetic appeal.

High-End Hand Tool Handle

This component is used in high-end handheld tools as the primary grip, combining structural strength with ergonomic feel. CNC chamfering is applied to the edges to ensure smooth assembly. After polishing to remove minor imperfections, the surface is finished with powder coating, providing wear resistance, corrosion protection, and a premium appearance.

High-End Home Appliance Rear Cover

This product is used in high-end home appliances as a rear cover providing protection and structural support, combining heat dissipation and decorative functions. It is manufactured using high-precision metal stamping, enabling stable batch production and structural integrity. Deburring operations are performed on edges and holes to ensure safety and smooth assembly. After polishing, the surface is coated with oil-based paint, enhancing surface finish and corrosion resistance.

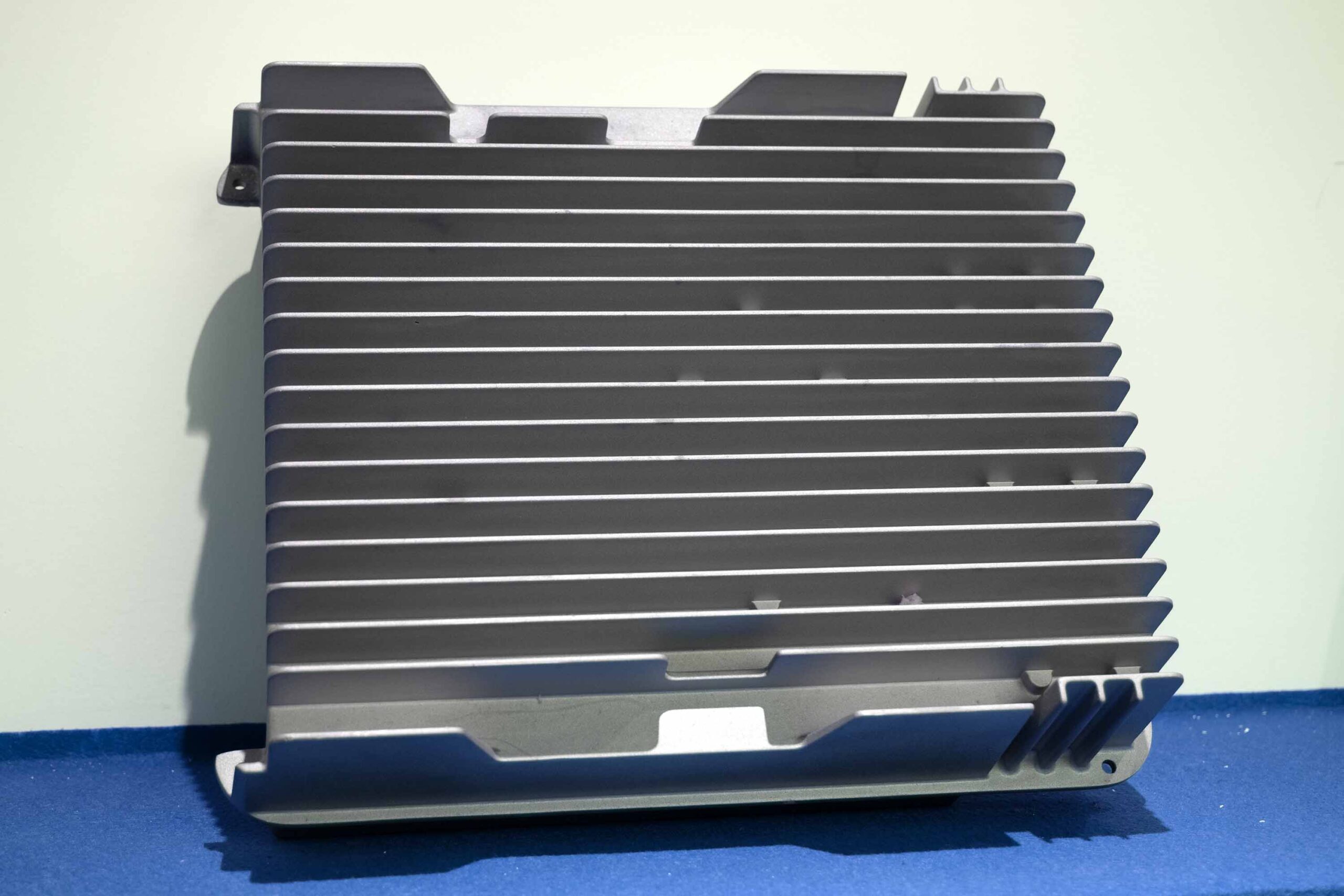

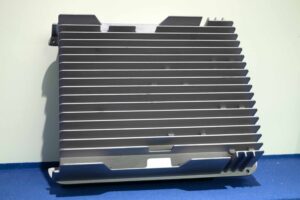

Aluminum Heat Sink Fins

The fins are manufactured using high-precision aluminum die casting, ensuring uniform structure and excellent thermal conductivity. Precision finishing operations including chamfering and deburring, tapping, and machining of holes are performed to ensure accurate assembly. The surface undergoes polishing and sandblasting, enhancing surface flatness and heat dissipation efficiency. Finally, coating is applied to improve corrosion resistance and achieve customized appearance.

High-Difficulty Ceramic-Coated Food-Grade Baking Tray

This product is an environmentally friendly, high-grade baking tray. It is manufactured using high-precision aluminum die casting, achieving lightweight design and high-strength structure. After initial polishing, precision machining of the back positioning holes is performed.

The surface is first sandblasted to enhance adhesion, followed by ceramic coating. The challenge lies in the poor adhesion of ceramic powder and the strict thickness control of 20–45 μm; excessive thickness may cause chipping, while insufficient thickness can lead to peeling. During heating, care must be taken to prevent the ceramic from sliding under gravity.

To address these challenges, we use high-quality raw materials to ensure…

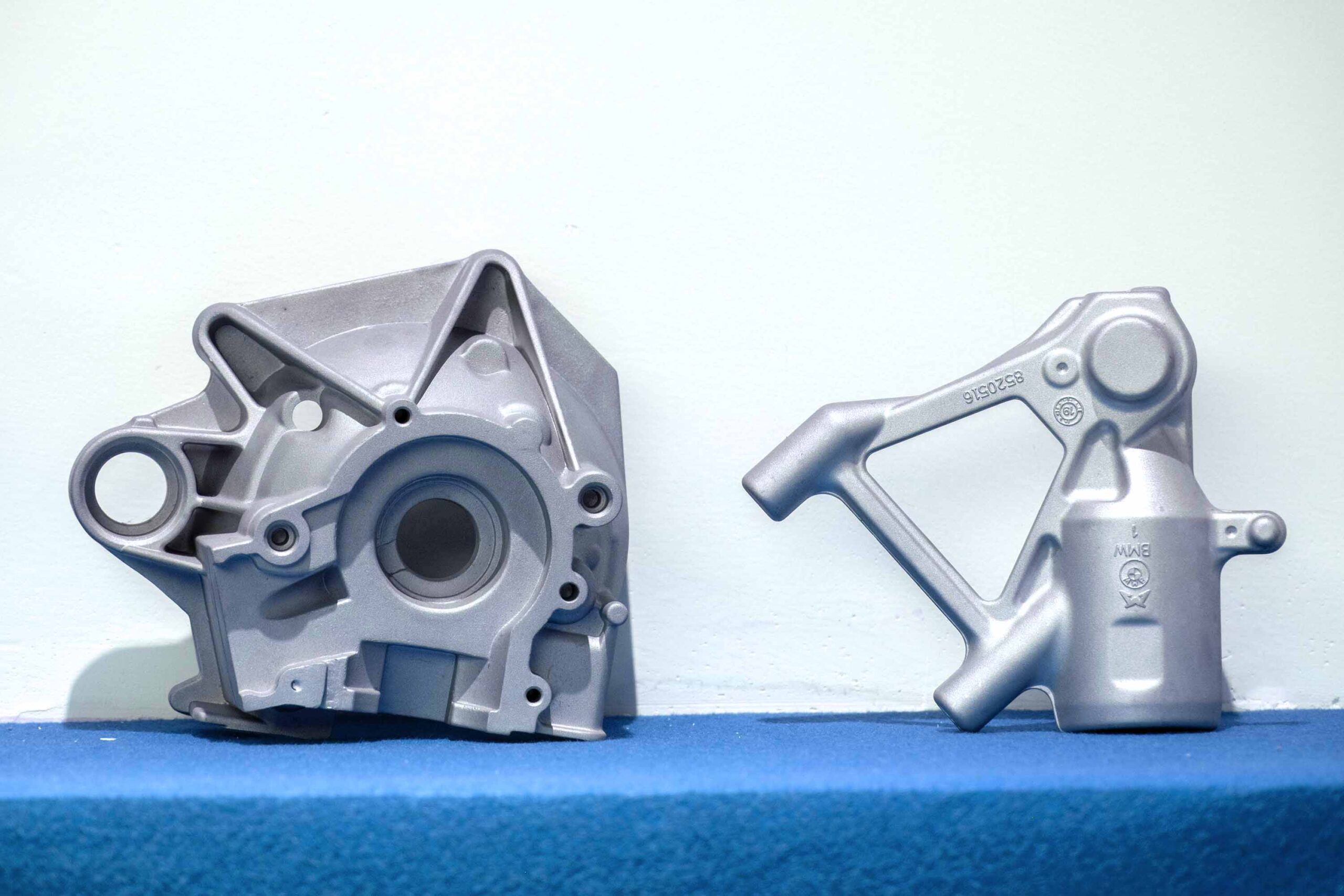

Medium-Sized Aluminum Die-Cast Automotive Structural Component

The component is manufactured using medium-sized aluminum die casting, achieving lightweight design and integrated forming, thereby reducing welding and assembly steps. Deburring and high-precision machining are performed, with critical end faces processed to tight tolerances to ensure assembly accuracy. Surface treatment includes deburring, ultrasonic cleaning, and sandblasting, removing residual contaminants and enhancing surface quality.

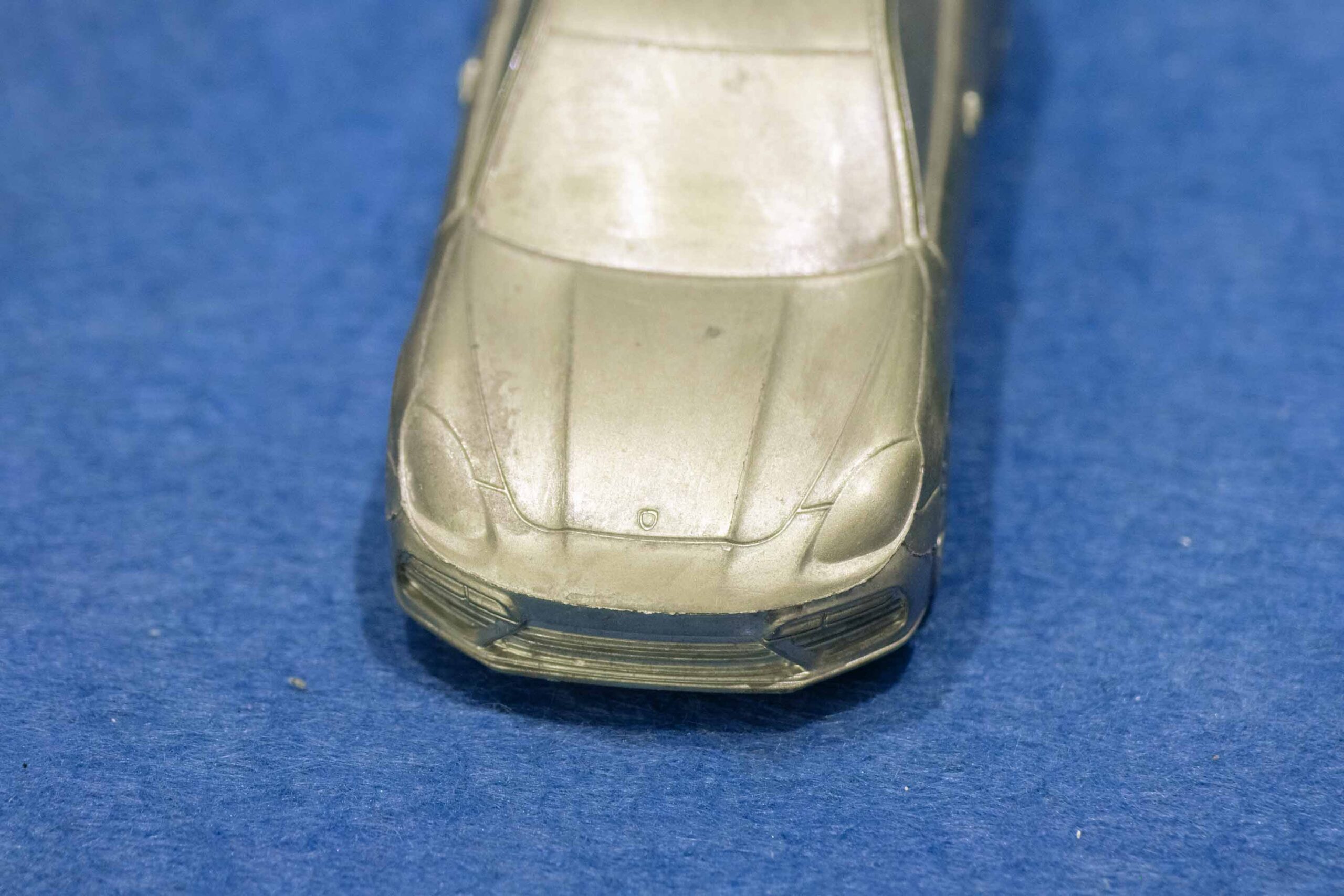

High-End Automotive Gift – Aluminum Die-Cast Component

This product serves as an high-end gift for a well-known automotive brand, combining brand presentation with practical functionality, and has strict requirements for precision and appearance. It is manufactured using high-precision aluminum die casting, with a focus on mold development and stable mass production for small, complex structural parts. The surface undergoes deburring and detailed finishing, ensuring smooth edges and structural integrity.

Professional Full-Metal Nail Gun Assembly

We provide all metal components for a professional-grade nail gun assembly, combining high strength, lightweight design, and assembly precision. Manufacturing processes include iron profile forming and machining, as well as aluminum die casting. Black aluminum die-cast parts are finished with painting, while red aluminum die-cast parts are treated with powder coating.

High-End Automotive Gift – Aluminum Extrusion Component

This component is an official high-end gift for a well-known automotive brand, with strict requirements for appearance and logo positioning accuracy, designed for brand presentation and premium customer gifting. It is formed by aluminum extrusion and CNC machined to ensure precise logo placement. The surface undergoes high-standard anodizing, guaranteeing consistent color and gloss.

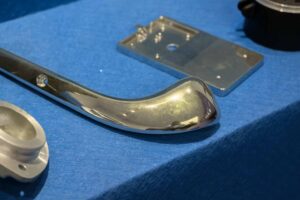

Electroplated Aluminum Die-Cast Lever

The lever is formed by aluminum die casting, followed by drilling and deburring to ensure assembly accuracy and initial surface preparation. It is then polished and electroplated, enhancing wear resistance and high-end visual appeal.

Sanitary Sliding Door Handle

The handle is formed by zinc die casting, achieving complex shapes and high-strength integrated forming. Precision machining includes polishing, deburring, chamfering, and drilling, ensuring smooth assembly and safe tactile feel. The surface is further treated with chrome plating, providing a bright, smooth finish with excellent corrosion resistance.

Aluminum Die-Cast Painted Lever

The lever is formed by aluminum die casting, followed by drilling and deburring to ensure assembly accuracy and initial surface preparation. It is then polished and painted, enhancing wear resistance and high-end visual appeal.

Premium Brand Knife Handle

The handle is used in international premium brand knives, combining aesthetic appeal, durability, and cost-effectiveness. It is formed by aluminum die casting, retaining certain flash features to ensure structural integrity. Stamping operations are then applied to quickly remove flash and burrs, eliminating the traditional deburring step and improving production efficiency. The surface is finished with powder coating, providing a wear-resistant and corrosion-resistant protective layer.

High-Precision Pneumatic Guide Rail

The component is used in high-end automation equipment and pneumatic transmission systems. It is formed by aluminum extrusion and undergoes high-precision drilling on a machining center to ensure hole accuracy meets pneumatic system requirements. From extrusion to drilling, tight tolerance control is maintained throughout the process. Full air-tightness inspection is performed to ensure leak-free performance.

Sanitary Industry Metal Component

The component is used for structural connections and decorative applications in sanitary products, with high requirements for corrosion resistance. It is formed from high-quality aluminum alloy, ensuring structural strength and stability. Machining operations are performed to achieve precise dimensions and complex geometries. The surface is treated with nickel plating, enhancing corrosion resistance and surface finish.

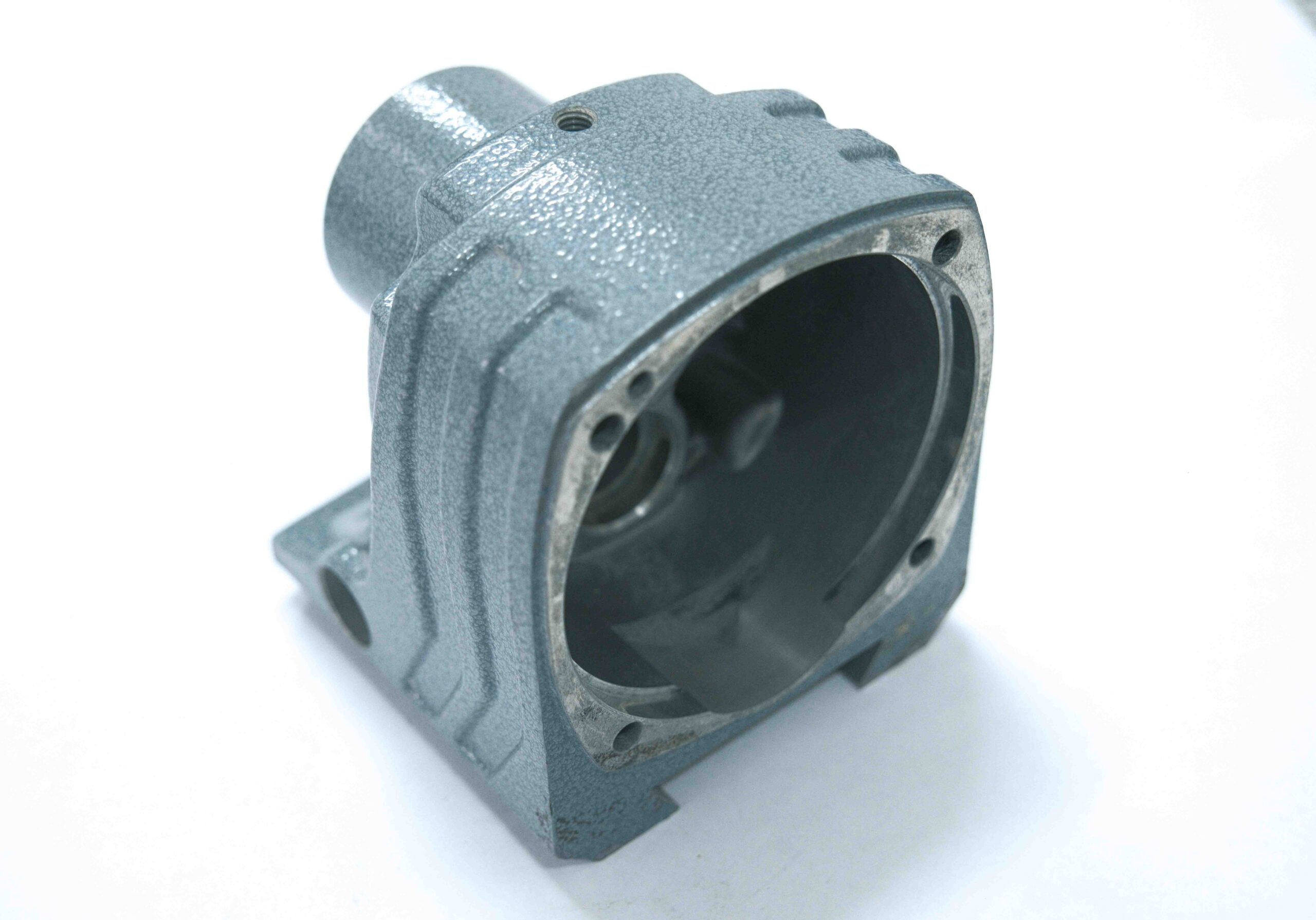

High-Precision Aluminum Die-Cast Component

The component is formed by aluminum die casting, ensuring structural stability and dimensional consistency. Deburring is applied to remove flash and sharp edges. Machining operations are performed to achieve high-precision holes, end faces, and assembly surfaces. The surface is ultrasonically cleaned to remove residual particles, oil, and fine contaminants.

High-End Sanitary Pull Rod

The product combines functional performance with decorative appeal. It is formed by zinc die casting, ensuring dense structure and smooth surface. Thread tapping and chamfering are applied to achieve precise threads and smooth edges. The surface undergoes polishing and chrome plating, resulting in a high-gloss, corrosion-resistant finish. Brand markings are applied using laser engraving.

Thin-Wall Precision Aluminum Die-Cast Metal Cover

The component is formed by aluminum die casting, with a specially optimized thin-wall design to achieve both lightweight and structural strength. Deburring is applied to ensure smooth, burr-free edges. The surface is polished, resulting in a uniform and refined appearance.

Powder-Coated Aluminum Die-Cast Component

The component is formed by aluminum die casting, ensuring dimensional stability and structural strength. Machining operations are performed to achieve critical dimensions and assembly hole accuracy. Deburring and cleaning are applied to remove flash, oil, and residues. The surface is finished with powder coating, enhancing corrosion resistance and decorative appearance.

CNC Machined Aluminum Billet Component

The component is machined from a single aluminum billet using CNC precision machining, achieving integrated forming and eliminating assembly misalignment. The surface undergoes anodizing, enhancing corrosion resistance and surface finish quality.

Powder-Coated Aluminum Die-Cast Component

The component is formed by aluminum die casting, ensuring dimensional stability and structural strength. Drilling operations are performed to create assembly and functional holes. The surface is finished with powder coating, enhancing corrosion resistance, scratch resistance, and visual appearance.

High-Precision Aluminum Profile Component

The component is formed using aluminum extrusion, followed by CNC drilling and chamfering for precision finishing. The surface undergoes anodizing, enhancing corrosion resistance, wear resistance, and aesthetic appearance.